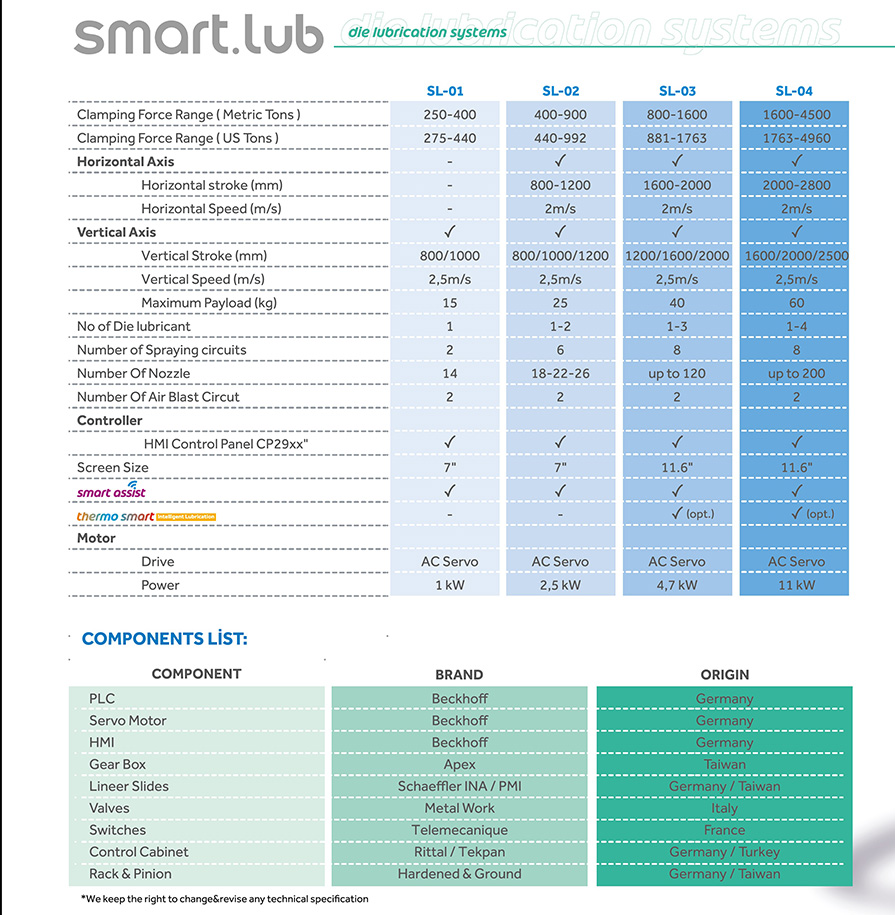

| Electro - Mechanical Properties |

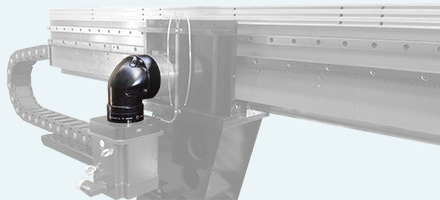

High performance servo motors

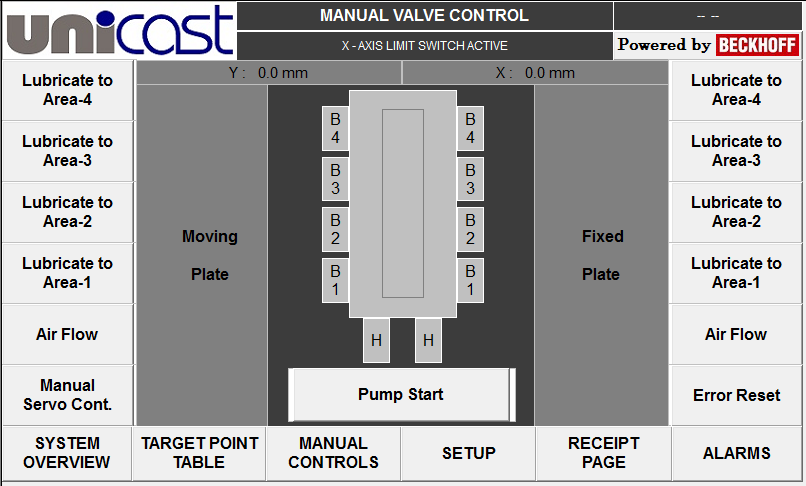

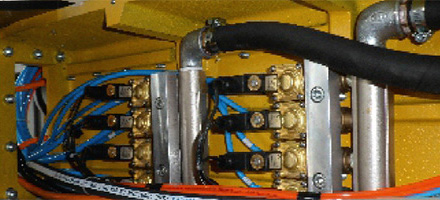

Powerful air purging and spray

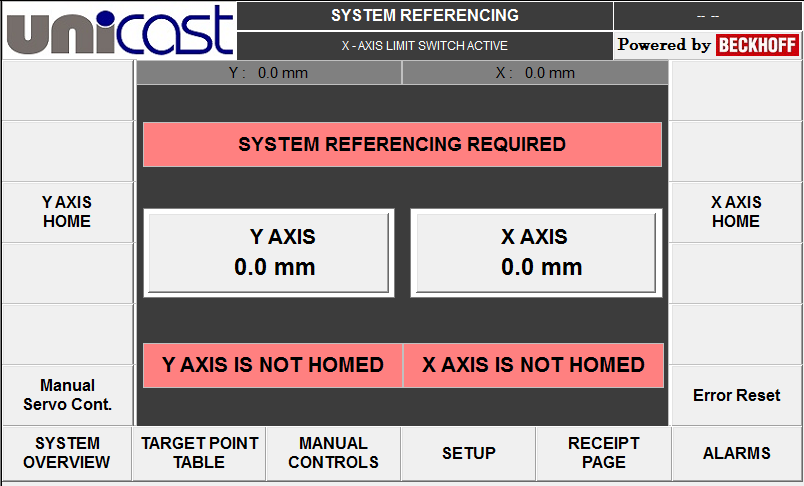

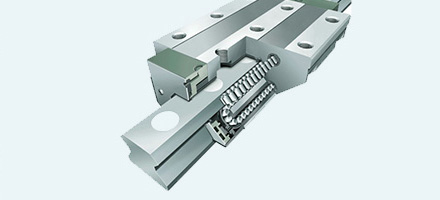

Precise positioning system

All components are easily accessible for maintenance

Protective bellows for Slides and Bearings

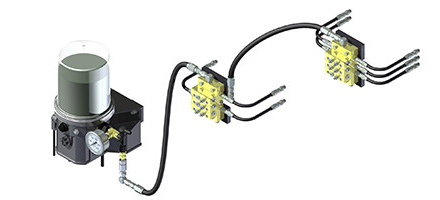

Automatic central lubrication system

Standard 3 band spraying head ( it may increase upon request)

Nozzle flow rate proportional adjustment with adjusting screw

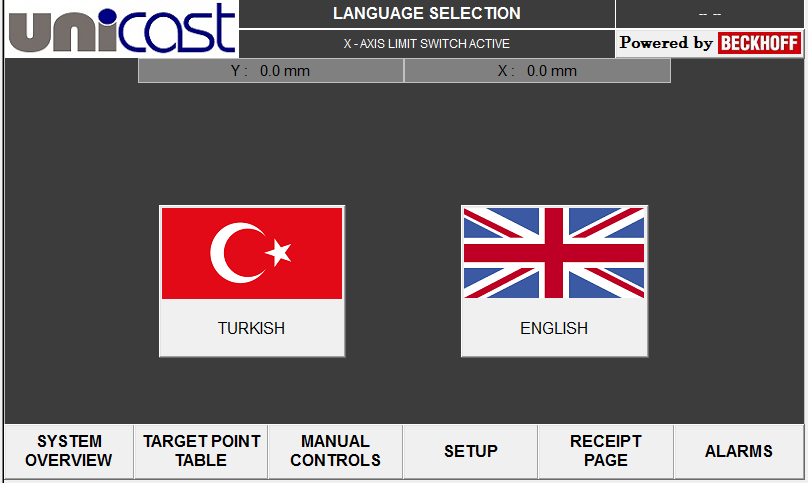

7” – 11,6” touch screen controller

User friendly controller with teach mode will permit you to set sprayer by just teaching the position.

Independent control of each spray circuit

Interface with die casting machine to control cores and pins while spraying

Up to 100 spraying programmes

-PLC-servo motor –driver-monitor kit have common programme and receiving programmes from PLC .

In case of any damage,just replace servo motor,driver or monitor and start the machine. |